| Author |

Message |

ryktnk

Joined: Apr 24, 2008

Posts: 285

Location: london

Audio files: 1

|

|

|

Back to top

|

|

|

oozitron

Joined: Apr 02, 2007

Posts: 38

Location: USA

|

Posted: Tue Sep 20, 2011 8:25 pm Post subject: Posted: Tue Sep 20, 2011 8:25 pm Post subject:

|

|

|

After a long time away, I'm coming back to this project... VER 2.1

I have wired up just a few controls for initial testing:

Max Stages = unwired = so it is "1"

Seq Mode = unwired = so it is "forward"

Step SubDiv = unwired = so it is "div by 1"

CV Out, Gate Out, Clock In = all wired up

Port time = all wired up (set to min)

CV range = wired to 5v

Per Stage:

LED = unwired

CV = YES wired up

Stage count = unwired

Gate mode = unwired

So I power it up and the CV slider for Stage 1 works perfectly, outputting 0v ~ 5v as expected.

Then I feed it ONE pulse into the CLOCK IN and the CV output goes from 0v and just goes down down down. I shut it off at this point thinking that damage might be happening.

Earlier I had a wiring problem that was making the TL074 get really hot. I've replaced the TL074.

Did I maybe fry my "2.1 programmed" chip?

thanks for any help...

Drew Drew |

|

|

Back to top

|

|

|

ryktnk

Joined: Apr 24, 2008

Posts: 285

Location: london

Audio files: 1

|

Posted: Sun Sep 25, 2011 8:12 am Post subject: Posted: Sun Sep 25, 2011 8:12 am Post subject:

|

|

|

| oozitron wrote: | After a long time away, I'm coming back to this project... VER 2.1

I have wired up just a few controls for initial testing:

Max Stages = unwired = so it is "1"

Seq Mode = unwired = so it is "forward"

Step SubDiv = unwired = so it is "div by 1"

CV Out, Gate Out, Clock In = all wired up

Port time = all wired up (set to min)

CV range = wired to 5v

Per Stage:

LED = unwired

CV = YES wired up

Stage count = unwired

Gate mode = unwired

So I power it up and the CV slider for Stage 1 works perfectly, outputting 0v ~ 5v as expected.

Then I feed it ONE pulse into the CLOCK IN and the CV output goes from 0v and just goes down down down. I shut it off at this point thinking that damage might be happening.

Earlier I had a wiring problem that was making the TL074 get really hot. I've replaced the TL074.

Did I maybe fry my "2.1 programmed" chip?

thanks for any help...

Drew Drew |

Hello

Sounds a bit odd.

For testing you really should have all the controls wire up

to the PIC, as floating inputs will create some unexpected results.

The CV out is affected by the GATE setting for each stage

[ the CV is only updated when the GATE is high ]

So the GATE switch needs to be set correctly for testing CV outputs.

What is the P-P voltage of you clock input ?

-ryk |

|

|

Back to top

|

|

|

adambee7

Joined: Apr 04, 2009

Posts: 420

Location: united kingdom

|

Posted: Sat Nov 05, 2011 11:23 am Post subject: Posted: Sat Nov 05, 2011 11:23 am Post subject:

|

|

|

Anyone got any s/pole 8 throw slide switches hanging around. i have a broken one.   |

|

|

Back to top

|

|

|

adambee7

Joined: Apr 04, 2009

Posts: 420

Location: united kingdom

|

Posted: Tue Nov 08, 2011 12:33 am Post subject: Posted: Tue Nov 08, 2011 12:33 am Post subject:

|

|

|

Hi Ryk, Sent you PM.   |

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

Posted: Mon Nov 21, 2011 4:10 am Post subject: Posted: Mon Nov 21, 2011 4:10 am Post subject:

|

|

|

Hello,

I have been going through stuff here, and i have a few m185 panels left.

The chances of me cutting any more of these now is slim.

Anyhow, i have the following -

1-off Gloss Black 3u Euro panel v2.1 O/S

1-off Silver with Blue infill (think Buchla style) 5u panel v2.0 O/S

1-off Silver with Blue infill (think Buchla style) 5u panel v2.1 O/S

1-off Matt Black with white infill 5u panel v2.0 O/S WITH Layout for per-stage Portamento switches.

I have some fastener sets left, although i may not have enough for all of the above - i would have to check. Fastener sets (well, and panels) availible on a first come first served basis.

All of the above are final revision panels.

Price - GBP 60 per panel. No difference in cost between formats / revisions. This offers no reduction on my last advertised price, however, as i say, this will probably be your last oppotunity for these items.

(i know that i can always cut more, but this panel requires so many cutter changes that theyre not the most economic to make in 1-off quantities, and there probably isnt enough demand to cut in more than 1-off quantities any more - hence the catch 22)

Fastener sets, whilst they last, are GBP 4 per set. These are the correct mix of M2 and M2.5 screws to match the switch sets Ryk sent out. The M2 screws are not the easiest to find in small quantities, hence me buying a load and making up sets. The fastener sets are in nice, shiny, stainless steel, allen cap configuration. Theyre the same manufacturer, but different configuration, to the units i use on the x0xb0x builds (so if youre wondering what they look like you can look at those photos)

I will try and take some photos of these panels, and update this post shortly.

Oh - one last thing. Im in the United Kingdom, but can, and do, ship world wide. Postage from me is always at cost price only. Packing is without charge. The company has accounts in GBP and Euro and cards can be processed using Google Checkout (surcharged at cost).

Thanks, Julian

_________________

For custom cnc engraved panels see - http://www.thebeast.co.uk/cnc/

|

|

|

Back to top

|

|

|

Bastian

Joined: May 23, 2011

Posts: 11

Location: Utrecht, The Netherlands

|

Posted: Sat Nov 26, 2011 3:55 am Post subject:

A bit late... Posted: Sat Nov 26, 2011 3:55 am Post subject:

A bit late... |

|

|

Hi ryk, Julian, others...

I see you're still busy with the project, can you tell me if there's any way of getting hold of a pcb and pic of the 2.1 version? The project keeps popping up in my mind now and then after hearing of it this summer.

I tried using the software version in combination with a midi to cv unit, but this is defenetely not the same

Are there files available to produce the pcb and pic yourself just to get started?

Bastian |

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

Posted: Sat Nov 26, 2011 7:33 am Post subject: Posted: Sat Nov 26, 2011 7:33 am Post subject:

|

|

|

Ryk will, im sure, confirm, but...

I think the PCBs will probably always be availible from Ryk, however, the switches were purchased by him in bulk somwhere, and theyre not easily found elsewhere.

So, if Ryk has none left, and is not intending on (or can not) get more, then that's that for the switches.

The project can, however, be built with rotary switches. When the project was more current, i laid out a panel for use with rotaries, however, then activity seemed to drop off, so i did not put the panel in to production.

It seems that most want to build with the slide switches, if they can get them.

_________________

For custom cnc engraved panels see - http://www.thebeast.co.uk/cnc/

|

|

|

Back to top

|

|

|

adambee7

Joined: Apr 04, 2009

Posts: 420

Location: united kingdom

|

Posted: Sat Nov 26, 2011 8:10 am Post subject: Posted: Sat Nov 26, 2011 8:10 am Post subject:

|

|

|

i'm thinking of building 2 more. thinking of mini rotary switches and porta on each step.   |

|

|

Back to top

|

|

|

adambee7

Joined: Apr 04, 2009

Posts: 420

Location: united kingdom

|

Posted: Sat Nov 26, 2011 8:16 am Post subject: Posted: Sat Nov 26, 2011 8:16 am Post subject:

|

|

|

the panels you did for me julian are nearly stuffed. just purchasing 4 10unit cases for them. people should see your work so i'll post pics up in the next month or so.   |

|

|

Back to top

|

|

|

nerdware

Joined: Jul 11, 2009

Posts: 91

Location: UK

|

Posted: Sat Nov 26, 2011 10:07 am Post subject: Posted: Sat Nov 26, 2011 10:07 am Post subject:

|

|

|

I've nearly sourced all the parts for mine. I'm just struggling a little with the LEDs and port switches - none of the LEDs and switches I have fit the holes, but that can be fixed.

BTW, my PIC has the 2.1 firmware, but it appears that I have a panel for the 2.0 firmware, with holes for the port switches. If I understand correctly, this means I can use the port switch mod and leave the Stage CV socket unused.

I'm trying think of a way to use that spare socket, but my modding skills are very poor. I'll be happy just to get this thing working! However, the best idea I have so far is to use a gate-to-trigger circuit to provide a Stage One pulse. Has anyone else done anything like this?

_________________

http://soundcloud.com/nerdware/

"render unto digital what is due to digital, render unto analogue what is due to analogue" |

|

|

Back to top

|

|

|

patchdub

Joined: Jan 21, 2009

Posts: 56

Location: Taos, NM

|

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

Posted: Sun Nov 27, 2011 2:38 am Post subject: Posted: Sun Nov 27, 2011 2:38 am Post subject:

|

|

|

for all the trouble supporting that switch from the panel, i think i would just use rotaries.

_________________

For custom cnc engraved panels see - http://www.thebeast.co.uk/cnc/

|

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

Posted: Mon Nov 28, 2011 10:23 am Post subject: Posted: Mon Nov 28, 2011 10:23 am Post subject:

|

|

|

| julian wrote: |

I will try and take some photos of these panels, and update this post shortly.

|

As promised, photos below -

V2.0 with portamento mod -

Euro in gloss black (v2.1) -

The silver/blue panels never look that great when i take photos of them, but if you look at the photo of the klee panel i cut for someone, it gives a much better idea of what they actually look like -

...and on to the m185s, in the same colour -

V2.0 in 'buchla' blue -

V2.1 in 'buchla' blue -

_________________

For custom cnc engraved panels see - http://www.thebeast.co.uk/cnc/

|

|

|

Back to top

|

|

|

nerdware

Joined: Jul 11, 2009

Posts: 91

Location: UK

|

Posted: Mon Nov 28, 2011 12:43 pm Post subject: Posted: Mon Nov 28, 2011 12:43 pm Post subject:

|

|

|

| julian wrote: | V2.0 with portamento mod -

|

That's the panel I have! It's great, but I'm having some difficulty finding the stage LEDs and port switches for it. The holes are much smaller than I expected, and the space for the port switches is very tight. If I use the Apem bladed toggle switches, there won't be enough space to mount them horizontally. I don't mind mounting them vertically, but I think that will make it harder to see which stages have port on.

I was going to ask if anyone could suggest an alternative switch, but now I see that Buchla blue 2.1 panel...That would solve two of my panel problems! Argh! Choices, choices!

_________________

http://soundcloud.com/nerdware/

"render unto digital what is due to digital, render unto analogue what is due to analogue" |

|

|

Back to top

|

|

|

Bastian

Joined: May 23, 2011

Posts: 11

Location: Utrecht, The Netherlands

|

Posted: Mon Nov 28, 2011 1:31 pm Post subject:

sliders and stuff Posted: Mon Nov 28, 2011 1:31 pm Post subject:

sliders and stuff |

|

|

| julian wrote: | Ryk will, im sure, confirm, but...

I think the PCBs will probably always be availible from Ryk, however, the switches were purchased by him in bulk somwhere, and theyre not easily found elsewhere.

So, if Ryk has none left, and is not intending on (or can not) get more, then that's that for the switches.

The project can, however, be built with rotary switches. When the project was more current, i laid out a panel for use with rotaries, however, then activity seemed to drop off, so i did not put the panel in to production.

It seems that most want to build with the slide switches, if they can get them. |

Good to hear, I've send a PM to ryk with this question. let's hope he still has some parts lying around.

For the buttons: the sliders have got this oldschool look  but on the other hand take up a lot of space. i've been looking around on the net for these, there are a lot of companies who still produce. Most of them are in the east (asia). In the past i've ordered some others as samples for a project at astronomic transport costs, but then my customer was paying but on the other hand take up a lot of space. i've been looking around on the net for these, there are a lot of companies who still produce. Most of them are in the east (asia). In the past i've ordered some others as samples for a project at astronomic transport costs, but then my customer was paying

Maybe i can try to get a quote for a small amount if there's a shared interest with other forum members.

Nice to hear the project is still going strong!

Bastian |

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

Posted: Mon Nov 28, 2011 3:20 pm Post subject: Posted: Mon Nov 28, 2011 3:20 pm Post subject:

|

|

|

| nerdware wrote: |

That's the panel I have! It's great, but I'm having some difficulty finding the stage LEDs and port switches for it.

|

The LEDs should just be 3mm ones. I deliberatly cut the holes close with the 3mm leds, so that no additional hardware is needed to hold the led, but, i guess, 3mm leds may vary in size some and complicate this approach.

If there is ever a choice though, i always cut for the smallest component that people will use. This is very much intentional, as, i figure, anyone with a set of drills can make a round hole larger, if they need to, using the existing hole as a guide, however, packing out a component, to hold in an oversized panel hole never ends up pretty...

The switches should just be the standard (cheap) minature (or sub min - i cant recall) from Rapid, etc.

Let me get some out of my parts cases tommorow, and fit some to the panel i have here to make certain, however, im almost 100% sure these are the ones (again, i try to make the panels as compatible as possible, so try hard to stay away from hard to get parts!)

Let me check tommorw though (may be late, as i have a busy day tommorow) and get back to you with the details.

Julian

_________________

For custom cnc engraved panels see - http://www.thebeast.co.uk/cnc/

|

|

|

Back to top

|

|

|

emdot_ambient

Joined: Nov 22, 2009

Posts: 667

Location: Frederick, MD

|

Posted: Mon Nov 28, 2011 3:55 pm Post subject:

Re: sliders and stuff Posted: Mon Nov 28, 2011 3:55 pm Post subject:

Re: sliders and stuff |

|

|

| Bastian wrote: | | ...the sliders...take up a lot of space. |

Uh...I beg to differ on that. Not when you're trying to pack in 8 of the 4P and 8 of the 8P switches. You actually use up a lot less spce like that than with rotary switches because with the slide switches arranged as Julian has them, you can get the switches pretty close together on the vertical axis. Take a look at Julian's V2.0 With Portamento Mod panel and try eyeballing it. Imagine adding 2 columns of rotaries to the right of the CV knobs. It can be done, but it's not as finger-friendly as with the slider switches.

I haven't found any 8P mini rotary switches that I can afford (plus I hate how the mini rotaries have tiny shafts that pretty much limit you to using the knobs that come with them...doesnt' fit my designs at all), and the less expensive rotaries have nearly 1" bodies. With 5U modules being about 8.75" high, that doesn't leave a lot of wiggle room behind the panel.

But keep in mind that these can be built with pots rather than switches. So both slider pots and rotary pots are viable options.

_________________

Looking for a certain ratio since 1978 |

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

Posted: Mon Nov 28, 2011 4:02 pm Post subject: Posted: Mon Nov 28, 2011 4:02 pm Post subject:

|

|

|

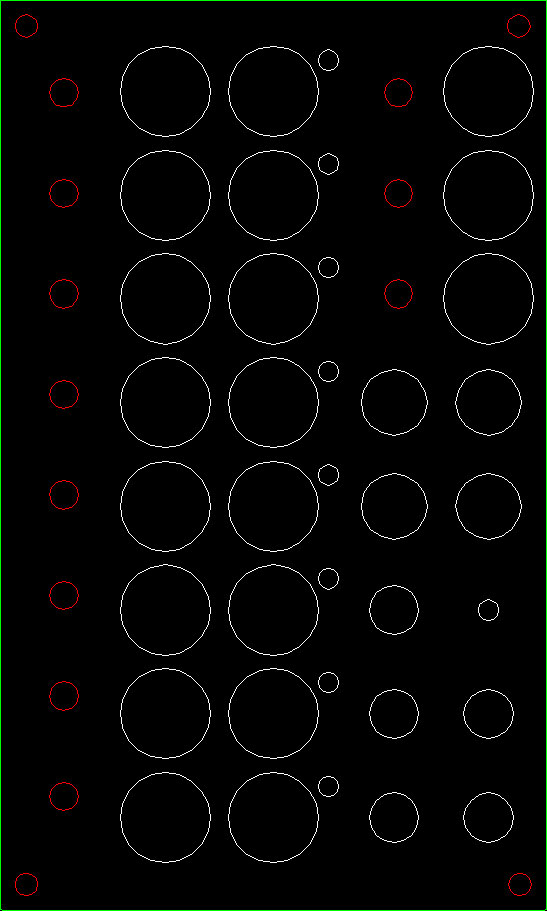

This panel -

..was laid out to be able to use these (cheap, widely availible) switches -

Like i say, i have not tested the panel yet, and i last worked on it, probably, over a year ago (!) but i think it should work, and i dont think it will really be much more cluttered than the slide switch version (remember, the large white cicles are *not* knobs, but the area the body of the switch takes up behind the panel)

_________________

For custom cnc engraved panels see - http://www.thebeast.co.uk/cnc/

|

|

|

Back to top

|

|

|

julian

Joined: Jan 11, 2008

Posts: 103

Location: UK

|

Posted: Mon Nov 28, 2011 4:08 pm Post subject: Posted: Mon Nov 28, 2011 4:08 pm Post subject:

|

|

|

....i guess what i am trying to say is that, whilst i (and many others) recieved the slide switches from Ryk, i do not think that the lack of availibilty of them now should kill this project.

Indeed, if i were to start over, i may even opt for using rotaries, rather than slide, simply due to their availibility. Again, i always try and stay away from 'rare' parts, so that i know things are repairable in the future, when they go wrong. For me, the use of a comonly availible part in a design is much more desirable than a rare one.

_________________

For custom cnc engraved panels see - http://www.thebeast.co.uk/cnc/

|

|

|

Back to top

|

|

|

emdot_ambient

Joined: Nov 22, 2009

Posts: 667

Location: Frederick, MD

|

Posted: Tue Nov 29, 2011 8:38 am Post subject: Posted: Tue Nov 29, 2011 8:38 am Post subject:

|

|

|

| julian wrote: | | ....i guess what i am trying to say is that, whilst i (and many others) recieved the slide switches from Ryk, i do not think that the lack of availibilty of them now should kill this project. |

Oh, totally agree!

I have slide switches for one, but not enough for 2 (and have 2 PCB). I've decided to use a few of the slide switches on a dual panel, but save the rest for other projects, and am using cheap rotaries for most of what's needed here...just haven't quite decided on the final format. Right now I've got a 3U high, 19" wide design...but might expand the height of that to incorporate additional modules and options.

_________________

Looking for a certain ratio since 1978 |

|

|

Back to top

|

|

|

adambee7

Joined: Apr 04, 2009

Posts: 420

Location: united kingdom

|

|

|

Back to top

|

|

|

Bastian

Joined: May 23, 2011

Posts: 11

Location: Utrecht, The Netherlands

|

Posted: Wed Jan 11, 2012 1:40 pm Post subject:

building the pcb Posted: Wed Jan 11, 2012 1:40 pm Post subject:

building the pcb

Subject description: looking for alternatives |

|

|

I've bought a spare pcb from a forum user.

I'm sourcing the parts to populate the board but some parts are discontinued. Can someone tell me if the following parts will do instead of the old ones?

old: 2N3819 (Vishay) new: MPF102_D27Z (Fairchild)

old: 4069UB new: 4069UBE

Thanks!

Bastian

(b.t.w. I'm trying to get some samples from china for the 1p8t switches from Kwanda Industrial Co. not sure if it's going to work, I'm waiting for a reply from them) |

|

|

Back to top

|

|

|

Bastian

Joined: May 23, 2011

Posts: 11

Location: Utrecht, The Netherlands

|

Posted: Sat Jan 14, 2012 12:17 pm Post subject:

Sliding switches Posted: Sat Jan 14, 2012 12:17 pm Post subject:

Sliding switches |

|

|

| It worked! They're sending 32 1p8t and 32 2p8t sample switches. |

|

|

Back to top

|

|

|

|