| Author |

Message |

loss1234

Joined: Jul 24, 2007

Posts: 1536

Location: nyc

Audio files: 41

|

|

|

Back to top

|

|

|

bugfight

Joined: Aug 02, 2007

Posts: 188

Location: Arlington, TX USA

|

Posted: Tue Sep 23, 2008 12:58 pm Post subject: Posted: Tue Sep 23, 2008 12:58 pm Post subject:

|

|

|

how about here?

http://stoogepanels.com/

now owned by doug wellington, a swell guy... |

|

|

Back to top

|

|

|

fluxmonkey

Joined: Jun 24, 2005

Posts: 708

Location: cleve

|

Posted: Tue Sep 23, 2008 1:28 pm Post subject:

Re: "stooge" style brackets? for sale? Posted: Tue Sep 23, 2008 1:28 pm Post subject:

Re: "stooge" style brackets? for sale? |

|

|

| loss1234 wrote: | anyone know where to buy the PCB brackets that used to be made by STOOGE?

or how to make them without special tools? i worry that if i use steel easy enough to bend, that it wont be strong enough to support standoffs and a pcb or two.

there is a link

http://www.wiseguysynth.com/larry/brackets/bracket-draw2.jpg

on how to make them and it specifies steel but others have said aluminum.

i just think i would be able to FIT so much more behind a panel if i used these.

any thoughts?

thanks |

i use aluminum, since i can cut it with snips (tho it takes some effort) instead of a shear, and bend it in a vice. actually, i often use very thin aluminum... between the bend, the stiffening due to the PCB itself, and support from flying wires, it's plenty sturdy even for gigging.

b

_________________

www.fluxmonkey.com |

|

|

Back to top

|

|

|

neandrewthal

Joined: May 11, 2007

Posts: 672

Location: Canada

|

Posted: Tue Sep 23, 2008 1:28 pm Post subject: Posted: Tue Sep 23, 2008 1:28 pm Post subject:

|

|

|

I just used galvanized step flashings from home depot. Can be cut with small shears, bent with your hands, and plenty strong enough to support multiple PCB's. A $.99 piece usually makes me 3 brackets.

_________________

" I went through quite a few trannies til I found one I liked" - Wild Zebra |

|

|

Back to top

|

|

|

Scott Stites

Janitor

Joined: Dec 23, 2005

Posts: 4127

Location: Mount Hope, KS USA

Audio files: 96

|

Posted: Tue Sep 23, 2008 1:33 pm Post subject: Posted: Tue Sep 23, 2008 1:33 pm Post subject:

|

|

|

| Quote: | | I just used galvanized step flashings from home depot. Can be cut with small shears, bent with your hands, and plenty strong enough to support multiple PCB's. A $.99 piece usually makes me 3 brackets. |

That's exactly what I do!

_________________

My Site |

|

|

Back to top

|

|

|

Danno Gee Ray

Joined: Sep 25, 2005

Posts: 1351

Location: Telford, PA USA

|

Posted: Tue Sep 23, 2008 5:35 pm Post subject: Posted: Tue Sep 23, 2008 5:35 pm Post subject:

|

|

|

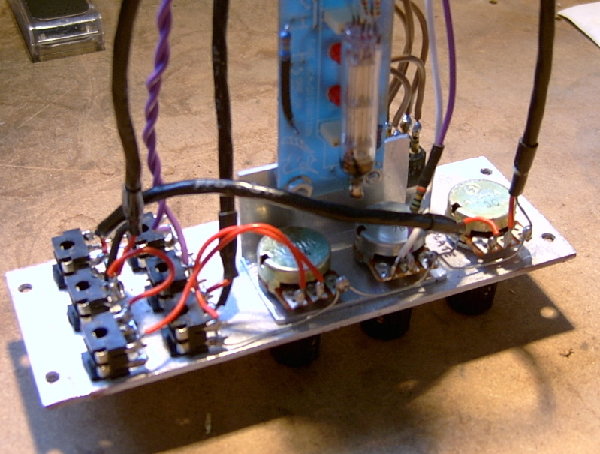

Okay Scott,

What is that beast you pictured there? could that be the mysterious MPS? |

|

|

Back to top

|

|

|

Dave Kendall

Joined: May 26, 2007

Posts: 421

Location: England

Audio files: 3

|

Posted: Tue Sep 23, 2008 6:25 pm Post subject: Posted: Tue Sep 23, 2008 6:25 pm Post subject:

|

|

|

Hi all.

For smaller formats (eurorack) I use 25mm x 25mm x1.5mm aluminium angle from the hardware store. All you need is a hacksaw, centre-punch, drill, and something to de-burr the holes. ( I sand mine down afterwards, but that's optional)

Nuts and bolts to hold PCB onto bracket are M3. The photos show a short length, holding a CGS65 tube VCA with clean/dirty mod, feedback pot with separate normalled I/O jacks, and 2 CV inputs jacks. The pot that doesn't go through the bracket is spaced from the panel rear with an M8 washer.

It's cheap, small, and strong enough.

cheers,

Dave

| Description: |

|

| Filesize: |

228.73 KB |

| Viewed: |

128 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

| Description: |

|

| Filesize: |

321.23 KB |

| Viewed: |

133 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

|

|

|

Back to top

|

|

|

clickmrmike

Joined: Jun 08, 2007

Posts: 48

Location: Gnashville

Audio files: 1

|

Posted: Tue Sep 23, 2008 7:14 pm Post subject: Posted: Tue Sep 23, 2008 7:14 pm Post subject:

|

|

|

Three pot versions are available from Synthesis Technologies.

Scott at Bridechamber has them in various sizes pre-drilled for CGS and MOTM, etc. About US$6.

(http://www.bridechamber.com/bridechamber.com/Brackets.html)

Good guy to deal with, etc...

clickmrmike |

|

|

Back to top

|

|

|

Scott Stites

Janitor

Joined: Dec 23, 2005

Posts: 4127

Location: Mount Hope, KS USA

Audio files: 96

|

Posted: Wed Sep 24, 2008 6:20 am Post subject: Posted: Wed Sep 24, 2008 6:20 am Post subject:

|

|

|

| Quote: | | What is that beast you pictured there? could that be the mysterious MPS? |

Nawp, that's my Triple Wilson SVVCF:

http://electro-music.com/forum/topic-17215.html

I might mention that when mounted vertically, using flashing is great, because on that axis they're very sturdy. However, when held horizontally, they're not solid at all and can move around. It works for me because I don't gig, but if I had to transport the synth, I'd remove the modules first. If you take the thing from gig to gig, I'd think the solid bracket would be more appropriate (Bridechamber or Doug Wellington).

Cheerios,

Scott

_________________

My Site |

|

|

Back to top

|

|

|

LetterBeacon

Joined: Mar 18, 2008

Posts: 454

Location: London, UK

|

Posted: Tue Jun 09, 2009 12:07 pm Post subject: Posted: Tue Jun 09, 2009 12:07 pm Post subject:

|

|

|

*BUMP*

I've got a big sheet of 0.8mm sheet aluminium that was planning to cut up to make PCB brackets. I bought some tin snips from eBay for the job (they look exactly like the ones Scott has in his picture). The only problem is that they don't seem to do the job at all! They only bend the metal, not cut it. Is the sheet aluminium too thin for the snips? Or are my snips in need of a sharpen? |

|

|

Back to top

|

|

|

|