| Author |

Message |

CreatorLes

Joined: Oct 05, 2014

Posts: 84

Location: San Antonio TX USA

|

Posted: Mon Apr 20, 2015 5:12 am Post subject:

wireLes Breadboards Posted: Mon Apr 20, 2015 5:12 am Post subject:

wireLes Breadboards

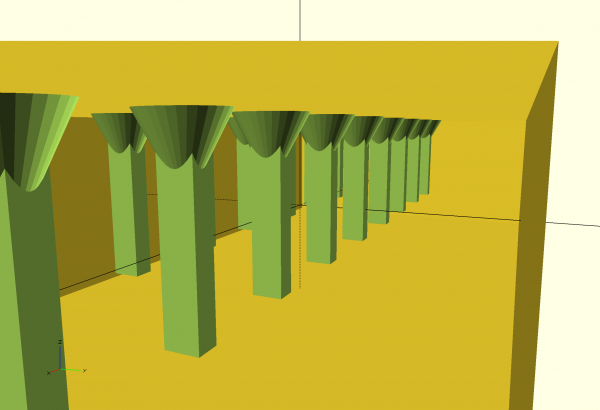

Subject description: breadboards without the wires, 3D printed in any shape |

|

|

This morning I was imagining what I could do chip-wise for my electro-music friends and I came up with an interesting idea - wireLes breadboards! These are breadboards 3D printed with no wires. So how do they work?

The holes that the chip's legs go into are intentionally designed to have enough room for a chip lead AND a wire! this is very low cost because it eliminates connecting mechanisms altogether. It is also solderable if you are careful enough not to melt the plastic (or even if you do a little bit).

Aha! you say - but what about multiple wires on a single pin? I'm thinking of a post or additional hole system for that, give me a little time, I just thunk this up a minute ago! In the mean time check out the images and let me know what you think!

Les

| Description: |

| top view of wireLes breadboard |

|

| Filesize: |

57.54 KB |

| Viewed: |

488 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

| Description: |

| inside view of wireLes breadboard |

|

| Filesize: |

42.85 KB |

| Viewed: |

455 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

|

|

|

Back to top

|

|

|

CreatorLes

Joined: Oct 05, 2014

Posts: 84

Location: San Antonio TX USA

|

|

|

Back to top

|

|

|

mosc

Site Admin

Joined: Jan 31, 2003

Posts: 18235

Location: Durham, NC

Audio files: 222

G2 patch files: 60

|

Posted: Mon Apr 20, 2015 10:40 am Post subject: Posted: Mon Apr 20, 2015 10:40 am Post subject:

|

|

|

I'm wondering, is it possible to print metal with these printers?

_________________

--Howard

my music and other stuff |

|

|

Back to top

|

|

|

CreatorLes

Joined: Oct 05, 2014

Posts: 84

Location: San Antonio TX USA

|

Posted: Mon Apr 20, 2015 11:19 am Post subject: Posted: Mon Apr 20, 2015 11:19 am Post subject:

|

|

|

I have two ways to print conductors, but they are very limited. Metal can be printed as a powder that is a small portion of the printing filament. You can then use sandpaper and other abrasives on the printed object to expose the metal and treat it somehow.

I bought some "Tinnit" which is a tinning solution that you buy as two powders. You mix the two powders in warm water and drop a circuit board into it and it "tins" the surface of the copper for you. Well, it tins 10 microns in size so I did a calculation once and reasoned that if I were to get some filament with copper in it, print s circuit board, sand it, then use the Tinnit, it might make a conductor. The result would be fragile so you could solder it to make it more sturdy. That's one possibility that I have-not tried.

Another is to print with carbon fiber PLA. Just like you can get filament with metal powder in it, you can get filament with Carbon fiber chopped up and put into the filament. SOME brands of carbon fiber filament are conductive with a conductivity around 1200 Ohms per centimeter squared. This is a huge conductivity so think 100's ok K and Megs with this stuff. It is probably suitable for CMOS and therefore Lunettas, so I'd like to experiment with it.

Just let me know if you have any ideas along these lines, I'll be happy to print test structures and whatnot for you free of charge (well, plus shipping if you want them mailed to you).

Les |

|

|

Back to top

|

|

|

|